À propos

Voici près de 50 ans que nous mettons son savoir-faire technique et notre passion de l’estampe au service des imprimeurs artisanaux, des étudiants et professeurs des écoles d'art et de tous les amateurs de belles impressions. Chaque jour, nous sélectionnons, fabriquons, commercialisons dans notre magasin à Paris, mais aussi en ligne, les produits nécessaires à toutes les techniques d’impression artisanale : Sérigraphie, Taille-Douce, Lithographie, Taille d’épargne. Nous organisons régulièrement des stages pour vous ouvrir les portes d’ateliers professionnels et pour vous faire découvrir ou vous perfectionner aux procédés d’impression. Grâce à notre expérience, en plus de la distribution des marques incontournables, nous concevons et mettons au point des papiers, des encres, des presses et des fournitures de qualité.

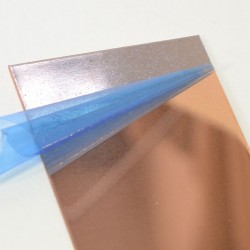

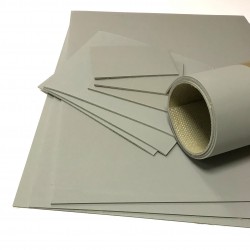

SÉLECTION JS litho

Plaques Polyester JS 33x50cm x10

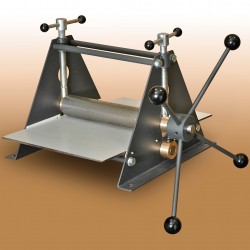

Sélection JS Taille-douce

25/11 Atelier de gravure par soulèvement du vernis

Atelier Impression taille-douce

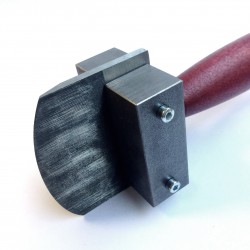

Sélection JS Taille d’épargne

Boîte Maruichi avec 5 gouges et 1 baren

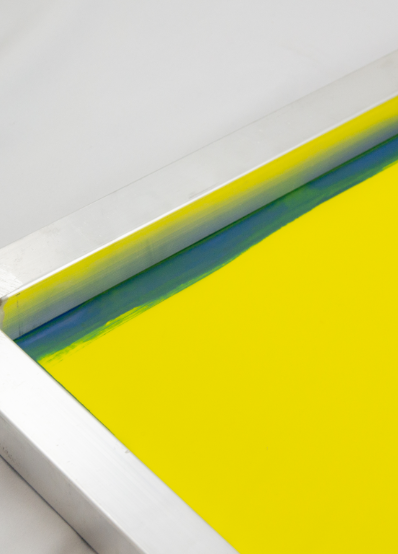

Sélection JS Sérigraphie

Promotions en cours

Séchoir à claies 100x152cm (*)

Armoire à plans 5 tiroirs A0 (*)

Armoire à plans 5 tiroirs A1 (*)